Quick Menu

Reduce Octane Giveaway – Increase Profitability

Using Process Instruments Raman technology, one 240,000 bpd Bay-area refinery achieved OCTANE GIVEAWAY savings of $3 million annually

- Raman accurately detects key high-octane contributors

- Benzene

- Toluene

- Iso-octane

- Xylenes

- Reduces

- Reprocessing of batches

- Tankage requirements

- Improves blend performance

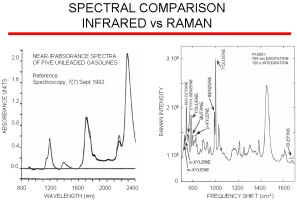

Note Raman’s improved spectra resolution

- Aromatics have a stronger spectral response with Raman than many other forms of spectroscopy (e.g., near-infrared spectroscopy [NIR])

- Single, full range octane model can measure all seasonal blends within 0.1 to 0.2 octane units

- Process Instruments guarantees that our Raman octane measurements always meet or exceed ASTM guidelines

- Unlike NIR, Raman is not sensitive to crude slate changes

- No need to develop unique models for different crudes

- Raman is a fundamental phenomenon

- Individual Raman peaks are narrow and discrete

- Eliminates overlapping peaks often seen in NIR spectra

- Raman models can be prepared normally with fewer calibration samples

- Models tend to

- Be more robust (last longer)

- Have improved standard errors of prediction (SEPs)

- Individual Raman peaks are narrow and discrete

- As with our Reid vapor pressure (RVP) modeling, full-range octane models can easily be divided into multiple, smaller sub-blend models that match seasonal and/or geographical blends